Dissolved Air Flotation Systems

Dissolved Air Flotation Systems Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 1 , , Unit Per Week

- Delivery Time

- 4-6 Week

- Sample Available

- No

- Main Export Market(s)

- South America, Eastern Europe, Middle East, Western Europe, Africa, Asia, Central America, North America, Australia

- Main Domestic Market

- All India

About Dissolved Air Flotation Systems

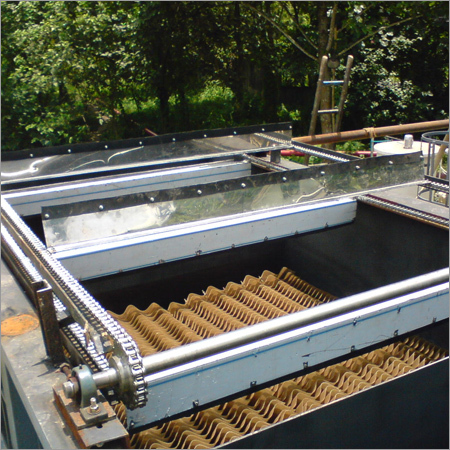

Dissolved Air Flotation Systems

Relying on the technical expertise & profound knowledge of our team, we have been successful in carving a niche for ourselves as a prominent manufacturer, suppliers & exporter of Air Floatation System. Our company does not compromise with the quality of offered range, so we use tested quality of raw materials during the manufacturing of these floatation systems. Due to its flexible selection, low noise and high efficiency, our Dissolved Air Flotation Systems is broadly used in water and chemical treatment plants.

Further Details

Dissolved Air Flotation Systems is a gravity separation process whereby the separation of two phases is achieved by increasing the specific gravity difference of the two phases. This is achieved by attaching micro air bubbles, brought about by saturating water with air under pressure, and then expanding the water stream through valves to atmospheric pressure. These micro bubbles nucleate onto the solid particles to be separated, thus lowering the specific gravity and allowing contaminants to rise to the surface.

Efficient Filtration Technology

Utilizing medium-grade filtration, our DAF systems target and capture dust particles with high efficiency, supporting healthier air quality in workspaces. The manual automation provides precise control over operations while simplifying maintenance and servicing routines.

Versatility Across Industries

Designed for adaptability, these systems suit a broad spectrum of industries including manufacturing, processing units, and service sectors. As both exporter and supplier, we cater to clients in India and abroad, assuring durable performance in diverse work environments.

FAQ's of Dissolved Air Flotation Systems:

Q: How does a Dissolved Air Flotation System operate as a dust collector?

A: The Dissolved Air Flotation System introduces air into the contaminated air or liquid stream, creating fine bubbles that attach to dust particles. These particles rise to the surface, allowing straightforward removal and resulting in cleaner air or liquid.Q: What industries commonly use this DAF system with medium filtration grade?

A: Industries that generate airborne particulates, such as manufacturing, food processing, and chemical plants, commonly use these DAF systems for environmental compliance and workplace safety.Q: When should you consider manual automation for a dust collector?

A: Manual automation is ideal for scenarios where customized adjustment, lower operational complexity, or cost-effectiveness is preferred over automated systems.Q: Where are your DAF systems manufactured and supplied from in India?

A: Our DAF systems are manufactured and supplied from our advanced facilities in India, ensuring prompt service as an exporter, manufacturer, and local supplier.Q: What is the process for installation and commissioning of these systems?

A: Installation involves securing the unit at the designated location, connecting it to the required electrical supply (220-240 Volt), and performing manual calibration. We provide guidance and support throughout commissioning.Q: How can clients benefit from using your Dissolved Air Flotation systems?

A: Clients benefit from improved air quality, regulatory compliance, and enhanced process efficiency. The medium filtration and durable construction ensure dependable, cost-effective performance in challenging industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS